Overcoming Challenges in Sample Handling With Thermo Autosamplers

When you’re working with Thermo autosamplers, you’re likely to encounter specific challenges in sample handling that can jeopardize your results. Maintaining sample integrity is crucial, but factors like viscosity variations and workflow inefficiencies can complicate matters. You might find that implementing best practices, such as regular calibration and proper needle selection, can make a significant difference. However, understanding the full scope of these challenges and the solutions available can lead to even more effective outcomes. What strategies have you considered to enhance your sample handling processes?

Common Sample Handling Challenges

When it comes to sample handling, you often face several challenges that can impact your results. One common issue is contamination, which can occur during the collection, storage, or transfer of samples. Even minute traces of foreign substances can skew your analysis and lead to inaccurate conclusions. It’s crucial to minimize exposure to potential contaminants throughout the process.

Another challenge is sample degradation. Many samples are sensitive to environmental factors like temperature, light, and time. If you’re not careful, your samples can lose their integrity before you even analyze them. Proper storage solutions and timely processing are essential to prevent this.

You might also struggle with inconsistent sample sizes. Variability in volumes can affect the reproducibility of your results. Standardizing your sample collection technique can help mitigate this issue.

Lastly, equipment limitations can impede your workflow. If your autosampler isn’t calibrated correctly or isn’t compatible with your sample types, you may face delays or errors. Regular maintenance and calibration checks are vital to ensure smooth operation.

Importance of Sample Integrity

Maintaining sample integrity is crucial to achieving reliable results in any analytical process. When you’re handling samples, even minor changes can lead to significant deviations in your results. Contamination, evaporation, and improper storage conditions can all compromise the quality of your samples.

You need to be vigilant about these factors to ensure that you’re working with data that accurately reflects the original sample.

Using Thermo Autosamplers can greatly enhance your ability to maintain sample integrity. These devices are designed to minimize human error and reduce the risk of contamination.

Automated processes ensure that samples are handled consistently, which is essential for producing reproducible results. Additionally, the temperature control features in these autosamplers help preserve volatile compounds and prevent degradation.

Addressing Viscosity Variations

Sample integrity often hinges on the physical properties of the samples being analyzed, including viscosity. High viscosity can lead to inconsistent sample delivery, which complicates analysis and can skew results. You need to address these variations to maintain accuracy and reliability in your work.

One effective strategy is to ensure that your Thermo autosampler is equipped with the right sampling needles and flow paths. These components should be chosen based on the viscosity of your samples. For thicker samples, using larger gauge needles can help facilitate smoother flow and prevent clogs.

Additionally, consider adjusting the sample temperature before analysis. Heating samples slightly can reduce viscosity and improve flow characteristics, making it easier for the autosampler to handle them.

Lastly, it’s crucial to regularly calibrate and maintain your autosampler. Regular checks can help you identify any issues that could affect performance, ensuring that it consistently delivers samples accurately, regardless of viscosity variations.

Optimizing Workflow Efficiency

To streamline your workflow efficiency with Thermo autosamplers, focus on integrating automation and strategic planning. Begin by assessing your current sample handling processes and identifying bottlenecks. By mapping out each step, you can pinpoint areas that require improvement, allowing you to implement automation where it counts the most.

Next, take advantage of the autosampler’s features. Use programmable methods to reduce manual intervention and minimize the risk of errors. Automating sample loading and analysis not only saves time but also enhances reproducibility and accuracy. You’ll find that consistent execution leads to better data quality.

Moreover, consider the layout of your workspace. Ensure that everything, from sample storage to the autosampler, is arranged for optimal accessibility. A well-organized environment can significantly reduce the time spent searching for materials or equipment.

Keep communication lines open with your team. Regular discussions about workflow improvements can foster a collaborative atmosphere where everyone contributes ideas for efficiency gains.

Best Practices autosampler for thermo Thermo Autosamplers

Using Thermo autosamplers effectively hinges on implementing best practices that ensure reliability and precision in your analyses. Start by calibrating your autosampler regularly. This helps maintain accuracy in your sample measurements and prevents errors that could compromise your results.

Next, ensure proper sample preparation. Use clean, compatible containers and avoid introducing contaminants that could skew your data.

Moreover, always monitor your autosampler’s performance. Regular checks can catch issues before they escalate, safeguarding your workflow.

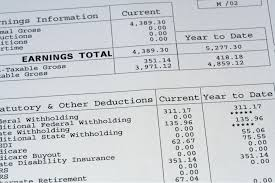

Here’s a quick reference table to help you remember these best practices:

| Best Practice | Description |

|---|---|

| Calibration | Regularly calibrate for accurate results |

| Sample Preparation | Use clean containers, avoid contaminants |

| Performance Monitoring | Regular checks to catch issues early |

Conclusion

In conclusion, tackling sample handling challenges with Thermo autosamplers is essential for achieving reliable results. By prioritizing sample integrity, addressing viscosity issues, and optimizing your workflow, you can significantly enhance your analytical processes. Implementing best practices and fostering communication within your team will not only streamline operations but also minimize errors and contamination risks. Embrace these strategies, and you’ll see a marked improvement in the accuracy and reproducibility of your sample analyses.