How to Choose the Right Flanges for Your Drainage Pipes

When it comes to selecting the right flanges for your drainage pipes, you’re faced with a multitude of options that can be overwhelming. You’re not just choosing a simple connector; you’re ensuring the integrity of your entire drainage system. As you begin to sift through the various types of flanges, you’ll need to consider factors like pipe type, environmental conditions, and material compatibility. But where do you start, and what are the key considerations that will ultimately lead you to the right flange for your specific needs?

Understanding Pipe Types and Flanges

When selecting flanges for drainage pipes, understanding the different types of pipes and flanges you’re working with is key.

You’ll typically work with pipes made of materials like PVC, ABS, or copper, each with its unique characteristics.

PVC pipes, for instance, are corrosion-resistant and relatively inexpensive, while copper pipes offer durability and high heat resistance.

You’ll also need to familiarize yourself with the different types of flanges, including slip-on, socket weld, lap joint, and threaded flanges.

Each type has its own set of applications and benefits.

Slip-on flanges, for example, are easy to install and offer a smooth, streamlined connection.

Socket weld flanges provide a strong, leak-resistant connection, but require more labor to install.

Lap joint flanges are suitable for low-pressure applications and offer flexibility in piping arrangements.

Environmental and Operating Conditions

Considering the environment and operating conditions of your drainage pipes is crucial in choosing the right flanges. You need to assess the temperature, pressure, and flow rate of the fluid or gas being transported through your pipes. This will help you determine the required flange size, type, and pressure rating.

For instance, high-temperature applications may require specialized flanges that can withstand extreme heat, while high-pressure applications may demand thicker, heavier-duty flanges.

You should also consider the pipe’s location and the surrounding environment. For example, pipes in areas prone to seismic activity or extreme weather conditions may require more robust flanges to ensure they can withstand external forces.

Additionally, flanges used in confined or hard-to-reach spaces may need to be designed with ease of installation and maintenance in mind. By taking these factors into account, you can select flanges that meet the specific demands of your drainage pipes and ensure safe, efficient operation.

Material Compatibility and Corrosion

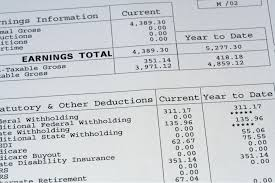

As you move forward with selecting the right flanges for your drainage pipes, it’s essential to prioritize material compatibility and corrosion resistance. You’ll want to ensure that the flange material can withstand the chemicals and substances that will flow through your pipes.

| Material | Corrosion Resistance | Common Use |

|---|---|---|

| Stainless Steel | Excellent | Chemical plants, hospitals, and food processing facilities |

| PVC | Good | Residential and commercial drainage systems |

| Cast Iron | Fair | Older buildings and infrastructure |

You’ll also need to consider the compatibility of the flange material with the pipe material. If the materials aren’t compatible, it can lead to corrosion and damage to the pipes. For example, if you’re using a PVC pipe, you’ll want to choose a flange made from a similar material to prevent corrosion.

You should also think about the operating conditions of your pipes, including temperature and pressure. This will help you choose a flange material that can withstand the conditions and prevent corrosion. By selecting the right flange material, you can ensure a safe and reliable drainage system.

Flange Size and Pressure Ratings

Material compatibility and corrosion resistance are just the starting points for selecting the right flanges. Once you’ve narrowed down your options based on these factors, you’ll need to consider the flange size and pressure ratings for your drainage pipes.

The size of the flange you choose will depend on the diameter of your pipe and the flow rate you need to achieve. Make sure to choose a flange that matches the size of your pipe to ensure a secure connection and prevent leaks.

In addition to size, you’ll also need to consider the pressure rating of your flange. This will depend on the maximum pressure your drainage system is expected to withstand. Different flanges have different pressure ratings, so it’s essential to choose one that can handle the maximum pressure in your system.

You can find the pressure rating for each flange type in the manufacturer’s specifications. By choosing a flange with the right size and pressure rating, you can ensure a safe and reliable connection for your 排水管 岐阜県 pipes.

Installation and Maintenance Considerations

When installing flanges for your drainage pipes, you’ll want to ensure a secure and watertight connection to prevent leaks and damage. This can be achieved by applying a suitable gasket material between the flange and the pipe, and then tightening the bolts in a star pattern to ensure even pressure.

Make sure to follow the manufacturer’s instructions for torque specifications to avoid over- or under-tightening.

During maintenance, inspect the flanges regularly for signs of wear or damage. Check the gaskets for signs of deterioration, and replace them as needed.

Also, inspect the bolts for signs of corrosion or damage, and replace them if necessary.

Proper installation and maintenance of flanges can help extend the lifespan of your drainage pipes and prevent costly repairs.

Consider using flanges with built-in features such as drain ports or test ports to make maintenance easier.

Additionally, consider using flanges made from materials that are resistant to corrosion and can withstand the harsh conditions of drainage systems.

Conclusion

Now that you’ve considered the key factors, you can choose the right flanges for your drainage pipes. Remember to match the flange to the pipe type, diameter, and required flow rate. Ensure the flange can handle the operating conditions, including temperature and pressure. With the right flange, you’ll minimize leaks, prevent corrosion, and extend the lifespan of your drainage system. Proper selection will also make installation and maintenance easier and more efficient.